| Grade |

Identification |

Size Inches |

Recommended A563 Nut |

Washer |

| Plain Finish |

Hot-Dip or Mechanical Zinc Coated |

| Grade |

Style |

Grade |

Style |

| 36 |

|

1⁄2 – 11⁄2 |

A |

Hex |

A |

Hex |

F436 |

| 15⁄8 – 4 |

A |

Heavy Hex |

A |

Heavy Hex |

| 55 |

|

1⁄2 – 11⁄2 |

A |

Hex |

A |

Heavy Hex |

F436 |

| 15⁄8 – 4 |

A |

Heavy Hex |

A |

Heavy Hex |

| 105 |

|

1⁄2 – 11⁄2 |

D1 |

Heavy Hex |

DH2 |

Heavy Hex |

F436 |

| 15⁄8 – 3 |

DH2 |

Heavy Hex |

DH2 |

Heavy Hex |

|

|

Nuts

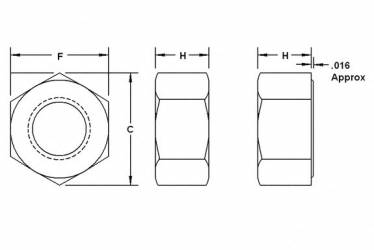

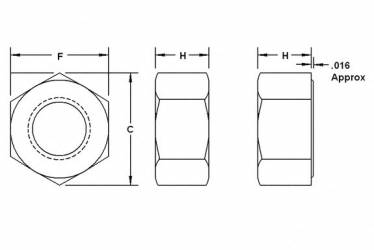

A563 Heavy Hex Nuts and Hex Nuts

The required nut specification for all F1554 anchor bolts is ASTM A563, which is the general nut specification for structural and mechanical applications. Depending on the diameter and finish of the anchor bolt, ASTM requires an A563 hex or heavy hex pattern nut. Heavy hex pattern nuts are slightly thicker and wider than hex nuts. The most common ASTM A563 grades found in the marketplace that are used with F1554 anchor bolts are A563 Grade A and A563 Grade DH. Low strength ASTM A563 Grade A nuts are found commonly in both hex and heavy hex patterns and are the recommend nut for both F1554 Grade 36 and F1554 Grade 55. A563 Grade DH high strength heavy hex nuts are required for use with F1554 Grade 105 high strength anchor bolts, however, A563 Grade DH nuts are often not available in certain diameters, finishes, or domestically manufactured. In these cases an A194 Grade 2H heavy hex nut can be substituted at any time to reduce cost. This substitution is specifically allowed at any time per ASTM A563 and is stated in the notes under Table 3 Mechanical Requirements in ASTM A563. A563 Grade DH nuts and A194 Grade 2H nuts can always be used with all three grades of F1554.

A563 Grades

| A |

Carbon steel, hex or heavy hex |

| B |

Carbon steel, hex or heavy hex |

| C |

Carbon steel, quenched and tempered, heavy hex |

| D |

Carbon steel, quenched and tempered, heavy hex |

| DH |

Carbon steel, quenched and tempered, heavy hex |

| C3 |

Weathering steel, quenched and tempered, heavy hex |

| DH3 |

Weathering steel, quenched and tempered, heavy hex |

A563 Mechanical Properties

| Grade |

Style |

Size, in. |

Proof Load, ksi |

Hardness, HBN |

| Plain |

Galvanized |

| A |

Hex |

1/4 - 1-1/2 |

90 |

68 |

116 - 302 |

| Heavy Hex |

1/4 - 4 |

100 |

75 |

116 - 302 |

| B |

Heavy Hex |

1/4 - 1 |

133 |

100 |

121 - 302 |

| Heavy Hex |

1-1/8 - 1-1/2 |

116 |

87 |

121 - 302 |

| C / C3 |

Heavy Hex |

1/4 - 4 |

144 |

144 |

143 - 352 |

| D |

Heavy Hex |

1/4 - 4 |

150 |

150 |

248 - 352 |

| DH / DH3 |

Heavy Hex |

1/4 - 4 |

175 |

150 |

248 - 352 |

| For UNC, 8UN, 6UN, and Coarse Pitch Threads |

A563 Chemical Properties

| Element |

Grades O, A, B, C |

D** |

DH** |

| Carbon |

0.55% max |

0.55% max |

0.20 - 0.55% |

| Manganese, min |

|

0.30% |

0.60% |

| Phosphorus, max |

0.12% |

0.04% |

0.04% |

| Sulfur, max |

0.15%* |

0.05% |

0.05% |

| * For grades O, A and B a sulfur content of 0.23% max is acceptable with the purchasers approval |

| ** For grades D and DH a sulfur content of 0.05 - 0.15% is acceptable provided the manganese is 1.35% min |

| Element |

Classes for Grade C3* |

DH3 |

| A |

B |

C |

D |

E |

F |

N |

| Carbon |

0.33 - 0.40% |

0.38 - 0.48% |

0.15 - 0.25% |

0.15 - 0.25% |

0.20 - 0.25% |

0.20 - 0.25% |

|

0.20 - 0.53% |

| Manganese |

0.90 - 1.20% |

0.70 - 0.90% |

0.80 - 1.35% |

0.40 - 1.20% |

0.60 - 1.00% |

0.90 - 1.20% |

|

0.40% min |

| Phosphorus |

0.040% max |

0.06 - 0.12% |

0.035% max |

0.040% max |

0.040% max |

0.040% max |

0.07 - 0.15% |

0.046% max |

| Sulfur, max |

0.050% |

0.050% |

0.040% |

0.050% |

0.040% |

0.040% |

0.050% |

0.050% |

| Silicon |

0.15 - 0.35% |

0.30 - 0.50% |

0.15 - 0.35% |

0.25 - 0.50% |

0.15 - 0.35% |

0.15 - 0.35% |

0.20 - 0.90% |

|

| Copper |

0.25 - 0.45% |

0.20 - 0.40% |

0.20 - 0.50% |

0.30 - 0.50% |

0.30 - 0.60% |

0.20 - 0.40% |

0.25 - 0.55% |

0.20% min |

| Nickel |

0.25 - 0.45% |

0.50 - 0.80% |

0.25 - 0.50% |

0.50 - 0.80% |

0.30 - 0.60% |

0.20 - 0.40% |

1.00% max |

0.20% min** |

| Chromium |

0.45 - 0.65% |

0.50 - 0.75% |

0.30 - 0.50% |

0.50 - 1.00% |

0.60 - 0.90% |

0.45 - 0.65% |

0.30 - 1.25% |

0.45% min |

| Vanadium |

|

|

0.020% min |

|

|

|

|

|

| Molybdenum |

|

0.06% max |

|

0.10% max |

|

|

|

0.15% min** |

| Titanium |

|

|

|

0.05% max |

|

|

|

|

| * Selection of a class shall be at the option of the manufacturer |

| ** Nickel or Molybdenum may be used. |

A194 Grade 2H Heavy Hex Nuts

Like A563 Grade DH, ASTM A194 Grade 2H is a high-strength nut with virtually identical mechanical requirements, but with additional heat treating and testing performed. This added heat treating and testing are required to ensure the nut performs at high temperatures. ASTM A194 is a high temperature and/or pressure bolting specification that is often used in piping or mechanical applications. Due to the mass-production of these nuts for these applications, A194 Grade 2H nuts are often widely available and are economical in certain diameters and finishes making them an excellent substitution for any A563 nut. In particular, A194 Grade 2H nuts are substituted and commonly used in place of A563 Grade DH heavy hex nuts.

A194 Chemical Properties

| Element |

2, 2H, and 2HM |

4 |

7 and 7M (AISI 4140) |

8 (AISI 304) |

8M (AISI 316) |

| Carbon |

0.40% min |

0.40 - 0.50% |

0.37 - 0.49% |

0.08% max |

0.08% max |

| Manganese |

1.00% max |

0.70 - 0.90% |

0.65 - 1.10% |

2.00% max |

2.00% max |

| Phosphorus, max |

0.040% |

0.035% |

0.035% |

0.045% |

0.045% |

| Sulfur, max |

0.050% |

0.040% |

0.040% |

0.030% |

0.030% |

| Silicon |

0.40% max |

0.15 - 0.35% |

0.15 - 0.35% |

1.00% max |

1.00% max |

| Chromium |

|

|

0.75 - 1.20% |

18.0 - 20.0% |

16.0 - 18.0% |

| Nickel |

|

|

|

8.0 - 11.0% |

10.0 - 14.0% |

| Molybdenum |

|

0.20 - 0.30% |

0.15 - 0.25% |

|

2.00 - 3.00% |

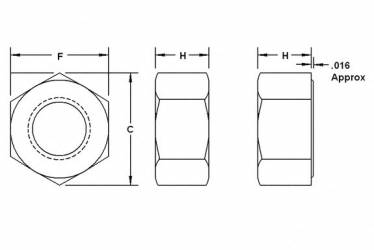

Heavy Hex Nut Dimensions

Click table to show drawing

| Bolt Diam. |

F |

C |

H |

Weight

(lbs.) |

| Width Across Flats |

Width Across Corners |

Thickness |

| Basic |

Max |

Min |

Max |

Min |

Basic |

Max |

Min |

| 1⁄2 |

7⁄8 |

0.875 |

0.850 |

1.010 |

0.969 |

31⁄64 |

0.504 |

0.464 |

0.07 |

| 5⁄8 |

11⁄16 |

1.062 |

1.031 |

1.227 |

1.175 |

39⁄64 |

0.631 |

0.587 |

0.12 |

| 3⁄4 |

11⁄4 |

1.250 |

1.212 |

1.443 |

1.382 |

47⁄64 |

0.758 |

0.710 |

0.20 |

| 7⁄8 |

17⁄16 |

1.438 |

1.394 |

1.660 |

1.589 |

55⁄64 |

0.885 |

0.833 |

0.30 |

| 1 |

15⁄8 |

1.625 |

1.575 |

1.876 |

1.796 |

63⁄64 |

1.012 |

0.956 |

0.43 |

| 11⁄8 |

113⁄16 |

1.812 |

1.756 |

2.093 |

2.002 |

17⁄64 |

1.139 |

1.079 |

0.59 |

| 11⁄4 |

2 |

2.000 |

1.938 |

2.309 |

2.209 |

17⁄32 |

1.251 |

1.187 |

0.79 |

| 13⁄8 |

23⁄16 |

2.188 |

2.119 |

2.526 |

2.416 |

111⁄32 |

1.378 |

1.310 |

1.02 |

| 11⁄2 |

23⁄8 |

2.375 |

2.300 |

2.742 |

2.622 |

115⁄32 |

1.505 |

1.433 |

1.31 |

| 15⁄8 |

29⁄16 |

2.562 |

2.481 |

2.959 |

2.828 |

119⁄32 |

1.632 |

1.556 |

1.62 |

| 13⁄4 |

23⁄4 |

2.750 |

2.662 |

3.175 |

3.035 |

123⁄32 |

1.759 |

1.679 |

2.04 |

| 17⁄8 |

215⁄16 |

2.938 |

2.844 |

3.392 |

3.242 |

127⁄32 |

1.886 |

1.802 |

2.41 |

| 2 |

31⁄8 |

3.125 |

3.025 |

3.608 |

3.449 |

131⁄32 |

2.013 |

1.925 |

2.99 |

| 21⁄4 |

31⁄2 |

3.500 |

3.388 |

4.041 |

3.862 |

213⁄64 |

2.251 |

2.155 |

4.19 |

| 21⁄2 |

37⁄8 |

3.875 |

3.750 |

4.474 |

4.275 |

229⁄64 |

2.505 |

2.401 |

5.64 |

| 23⁄4 |

41⁄4 |

4.250 |

4.112 |

4.907 |

4.688 |

245⁄64 |

2.759 |

2.647 |

7.38 |

| 3 |

45⁄8 |

4.625 |

4.475 |

5.340 |

5.102 |

261⁄64 |

3.013 |

2.893 |

9.50 |

| 31⁄4 |

5 |

5.000 |

4.838 |

5.774 |

5.515 |

33⁄16 |

3.252 |

3.124 |

11.94 |

| 31⁄2 |

53⁄8 |

5.375 |

5.200 |

6.207 |

5.928 |

37⁄16 |

3.506 |

3.370 |

15.26 |

| 33⁄4 |

53⁄4 |

5.750 |

5.562 |

6.640 |

6.341 |

311⁄16 |

3.760 |

3.616 |

18.12 |

| 4 |

61⁄8 |

6.125 |

5.925 |

7.073 |

6.755 |

315⁄16 |

4.014 |

3.862 |

21.80 |

|

Dimensions per ASME B18.2.2 1987 (1999)

|

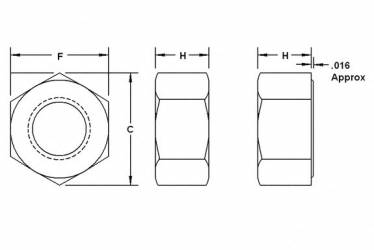

Hex Nut Dimensions

Click table to show drawing

| Nominal Size |

F |

C |

H |

Part Numbers |

| Width Across Flats |

Width Across Corners |

Thickness |

Domestic |

Import |

| Basic |

Max |

Min |

Max |

Min |

Basic |

Max |

Min |

Plain |

Galvanized |

Plain |

Galvanized |

| 1⁄2 |

3⁄4 |

0.750 |

0.736 |

0.866 |

0.840 |

7⁄16 |

0.448 |

0.427 |

16270 |

16271 |

11701 |

11702 |

| 5⁄8 |

15⁄16 |

0.938 |

0.922 |

1.083 |

1.051 |

35⁄64 |

0.559 |

0.535 |

16272 |

16273 |

11703 |

11704 |

| 3⁄4 |

11⁄8 |

1.125 |

1.088 |

1.299 |

1.240 |

41⁄64 |

0.665 |

0.617 |

16274 |

16275 |

11705 |

11706 |

| 7⁄8 |

15⁄16 |

1.312 |

1.269 |

1.516 |

1.447 |

3⁄4 |

0.776 |

0.724 |

16276 |

16277 |

11707 |

11708 |

| 1 |

11⁄2 |

1.500 |

1.450 |

1.732 |

1.653 |

55⁄64 |

0.887 |

0.831 |

16278 |

16279 |

11709 |

11710 |

| 11⁄8 |

111⁄16 |

1.688 |

1.631 |

1.949 |

1.859 |

31⁄32 |

0.999 |

0.939 |

16280 |

16281 |

11711 |

11712 |

| 11⁄4 |

17⁄8 |

1.875 |

1.812 |

2.165 |

2.066 |

11⁄16 |

1.094 |

1.030 |

16282 |

16283 |

11713 |

11714 |

| 13⁄8 |

21⁄16 |

2.062 |

1.994 |

2.382 |

2.273 |

111⁄64 |

1.206 |

1.138 |

- |

- |

11715 |

11716 |

| 11⁄2 |

21⁄4 |

2.250 |

2.175 |

2.598 |

2.480 |

19⁄32 |

1.317 |

1.245 |

16286 |

16287 |

11717 |

11718 |

|

Dimensions per ASME B18.2.2 1987 (1999)

|

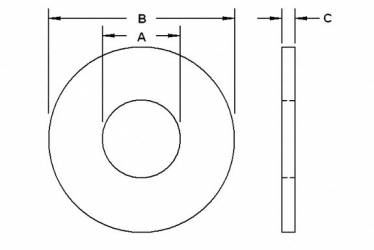

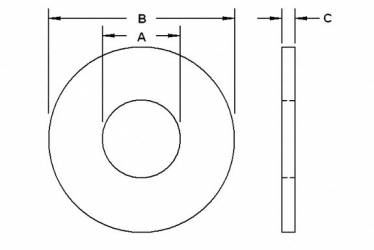

Washers

F436 Washers

Unless otherwise specified ASTM F1554 requires a F436 type 1 hardened washer. This washer is a common mass-produced washer typically used with structural bolts and high-strength bolts of many different specifications. Unlike the general purpose and low grade F844 washer, the F436 washer is heat treated to a required hardness range and is designed for mechanical and structural use. The dimensions below show the standard dimensions for stock F436 washers that are economical and readily available. Custom F436 washers that can be thicker, square, or much larger can be custom manufactured, but at much higher cost and longer lead time.

F436 Mechanical Properties

| Plain Finish |

Hot Dip Galvanized |

| Rockwell Hardness 38 to 45 HRC |

Rockwell Hardness 26 to 45 HRC |

F436 Chemical Requirements

| Element |

Type 1 |

Type 3 |

| Phosphorous, max |

0.040% |

0.040% |

| Sulfur, max |

0.050% |

0.050% |

| Silicon |

- |

0.15 - 0.35% |

| Chromium |

- |

0.45 - 0.65% |

| Nickel |

- |

0.25 - 0.45% |

| Copper |

- |

0.25 - 0.45% |

| Weathering steel washer may also be made from any of the steels listed in Table 2 of A325. |

Hardened Washer Dimensions

Click table to show drawing

| Bolt Size |

B |

A |

C |

Weight (lbs.)

Per 1000 Pieces |

Part Numbers |

| Outside Diameter |

Inside Diameter |

Thickness |

Domestic |

| Min |

Max |

Plain |

Galvanized |

| 1⁄2 |

11⁄16 |

17⁄32 |

0.097 |

0.177 |

18 |

16440 |

16441 |

| 5⁄8 |

15⁄16 |

11⁄16 |

0.122 |

0.177 |

33 |

16442 |

16443 |

| 3⁄4 |

115⁄32 |

13⁄16 |

0.122 |

0.177 |

41 |

16444 |

16445 |

| 7⁄8 |

13⁄4 |

15⁄16 |

0.136 |

0.177 |

64 |

16446 |

16447 |

| 1 |

2 |

11⁄16 |

0.136 |

0.177 |

82 |

16448 |

16449 |

| 11⁄8 |

21⁄4 |

13⁄16 |

0.136 |

0.177 |

105 |

16450 |

16451 |

| 11⁄4 |

21⁄2 |

13⁄8 |

0.136 |

0.177 |

133 |

16452 |

16453 |

| 13⁄8 |

23⁄4 |

11⁄2 |

0.136 |

0.177 |

163 |

16454 |

16455 |

| 11⁄2 |

3 |

15⁄8 |

0.136 |

0.177 |

200 |

16456 |

16457 |

| 15⁄8 |

31⁄4 |

13⁄4 |

0.178 |

0.28 |

320 |

19481* |

19482* |

| 13⁄4 |

33⁄8 |

17⁄8 |

0.178 |

0.28 |

307 |

16458 |

16459 |

| 17⁄8 |

31⁄2 |

2 |

0.178 |

0.28 |

360 |

16471* |

16472 |

| 2 |

33⁄4 |

21⁄8 |

0.178 |

0.28 |

380 |

16460 |

16461 |

| 21⁄4 |

4 |

23⁄8 |

0.24 |

0.34 |

560 |

16462 |

16463 |

| 21⁄2 |

41⁄2 |

25⁄8 |

0.24 |

0.34 |

720 |

16464 |

16465 |

| 23⁄4 |

5 |

27⁄8 |

0.24 |

0.34 |

920 |

16611 |

16612 |

| 3 |

51⁄2 |

31⁄8 |

0.24 |

0.34 |

1040 |

16613 |

16614 |

| 31⁄4 |

6 |

33⁄8 |

0.24 |

0.34 |

1350 |

- |

- |

| 31⁄2 |

61⁄2 |

35⁄8 |

0.24 |

0.34 |

1633 |

18490 |

18460 |

| 33⁄4 |

7 |

37⁄8 |

0.24 |

0.34 |

1880 |

- |

- |

| 4 |

71⁄2 |

41⁄8 |

0.24 |

0.34 |

2200 |

18461 |

18462 |

Dimensions per ASTM F436

*Usually domestic |

Other Accessories

Anchor sleeves

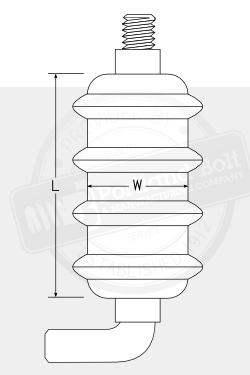

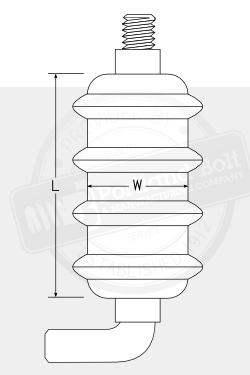

The alignment of anchor bolts and setting them perfectly into concrete in the required location so that the structure or equipment can fit perfectly over the anchor bolts is a difficult task. Often anchor bolt sleeves are specified to make this process easier and more forgiving. Anchor sleeves create a cavity or void in the concrete where the anchor bolt can be minutely adjusted in the case that an anchor bolt is slightly out of alignment and needs to be adjusted to fit the structure. Later, the space that the sleeve creates for adjustment is filled in with grout after fit is assured. Portland Bolt carries both Wilson Anchor Bolt Sleeves and Contec Anchor Bolt Sleeves. At times an engineer may specify a custom sleeve that consists of a steel pipe that is welded to an anchor bolt or anchor bolt embed plate. These welded pipe sleeves are highly custom and are designed by an engineer.

The alignment of anchor bolts and setting them perfectly into concrete in the required location so that the structure or equipment can fit perfectly over the anchor bolts is a difficult task. Often anchor bolt sleeves are specified to make this process easier and more forgiving. Anchor sleeves create a cavity or void in the concrete where the anchor bolt can be minutely adjusted in the case that an anchor bolt is slightly out of alignment and needs to be adjusted to fit the structure. Later, the space that the sleeve creates for adjustment is filled in with grout after fit is assured. Portland Bolt carries both Wilson Anchor Bolt Sleeves and Contec Anchor Bolt Sleeves. At times an engineer may specify a custom sleeve that consists of a steel pipe that is welded to an anchor bolt or anchor bolt embed plate. These welded pipe sleeves are highly custom and are designed by an engineer.

Anchor Sleeve Dimensions

Click table to show drawing

| Wilson Sleeves |

Contec Sleeves |

| Bolt Size |

Shell Size

W x L |

Part Number |

Color Code |

Shell Size

W x L |

Part Number |

| 1⁄2" |

2" x 5" |

18255 |

yellow |

2" x 5" |

18296 |

| 3⁄4" |

- |

| 5⁄8" |

2" x 7" |

18256 |

white |

2" x 7" |

18297 |

| 3⁄4" |

18257 |

| 7⁄8" |

18258 |

| 1" |

3" x 10" |

18259 |

green |

3" x 10" |

18298 |

| 11⁄4" |

18260 |

| 11⁄2" |

4" x 15" |

18261 |

red |

4" x 15" |

18299 |

| 13⁄4" |

18262 |

| 2" |

4" x 18" |

18263 |

blue |

4" x 18" |

18300 |

| 21⁄4" |

18264 |

| 21⁄2" |

6" x 24" |

18265 |

brown |

6" x 24" |

18301 |

| 3" |

18482 |

| 4" |

- |

- |

black |

6" x 24" |

18302 |

| 5" |

Plates

Square plates, embedded plates, and templates are all commonly used with F1554 anchor bolts. It is very typical for square plates to be used in place of F436 washers on the projecting threaded end of the anchor bolt, but perhaps even more common is to weld or fix in place a square plate at the bottom of the anchor bolt for pull out resistance. Embed plates can be round or square and are custom manufactured per an engineer’s requirement for the specific foundation calculated loads. It is typical for these embed or top washer plates to be made from A36 or A572 Grade 50 steel.

Templates and assemblies

Anchor bolts are often grouped in sets of two, four, six, eight, or more and are set into concrete using templates that keep the formation of the foundation in the pattern required. Templates can be used at the top of the anchor bolts as a “throw-away” template or can be pre-assembled with templates at the top and bottom of the assembly to hold the anchor bolts perfectly in place during shipping and concrete placement. Sometimes the bottom template is also a structural embed plate that serves for pull-out resistance and also as a template to hold the designed pattern together. Anchor bolt assemblies can be shipped loose without any assembly to reduce shipping cost and then assembled onsite or can be pre-assembled and shipped in marked assemblies. Fully assembled anchor bolt assemblies are laborious and increase shipping volume, but often greatly reduce onsite labor and create a more seamless product that can be used right off the truck or easily stored without worry about parts going missing.

The alignment of anchor bolts and setting them perfectly into concrete in the required location so that the structure or equipment can fit perfectly over the anchor bolts is a difficult task. Often anchor bolt sleeves are specified to make this process easier and more forgiving. Anchor sleeves create a cavity or void in the concrete where the anchor bolt can be minutely adjusted in the case that an anchor bolt is slightly out of alignment and needs to be adjusted to fit the structure. Later, the space that the sleeve creates for adjustment is filled in with grout after fit is assured. Portland Bolt carries both Wilson Anchor Bolt Sleeves and Contec Anchor Bolt Sleeves. At times an engineer may specify a custom sleeve that consists of a steel pipe that is welded to an anchor bolt or anchor bolt embed plate. These welded pipe sleeves are highly custom and are designed by an engineer.

The alignment of anchor bolts and setting them perfectly into concrete in the required location so that the structure or equipment can fit perfectly over the anchor bolts is a difficult task. Often anchor bolt sleeves are specified to make this process easier and more forgiving. Anchor sleeves create a cavity or void in the concrete where the anchor bolt can be minutely adjusted in the case that an anchor bolt is slightly out of alignment and needs to be adjusted to fit the structure. Later, the space that the sleeve creates for adjustment is filled in with grout after fit is assured. Portland Bolt carries both Wilson Anchor Bolt Sleeves and Contec Anchor Bolt Sleeves. At times an engineer may specify a custom sleeve that consists of a steel pipe that is welded to an anchor bolt or anchor bolt embed plate. These welded pipe sleeves are highly custom and are designed by an engineer.